Digital Twins and PLM: Creating Digital Twins of Chemical Products for Lifecycle Optimization

This article builds on those foundations, connecting the dots between R&D, manufacturing, and post-market insights. Here, we explore how an integrated PLM-digital twin ecosystem creates a continuous, data-driven feedback loop—one that spans the entire product lifecycle, accelerates innovation, and strengthens regulatory and sustainability performance. We listed other complementary content in the end.

1. Introduction: The Shift Toward Virtual Chemistry

The chemical industry is entering a phase of rapid transformation. Regulatory pressure, sustainability targets, and the need for faster innovation are converging, pushing companies toward more data-driven, integrated approaches to product lifecycle management (PLM).

One of the most powerful enablers in this transformation is the digital twin — a dynamic, data-fed virtual replica of a physical product or process that continuously reflects its real-world counterpart. In industries like aerospace and automotive, digital twins have been embraced for years to optimize performance and reduce costs. Now, chemical manufacturers are realizing the same technology can be adapted to manage formulations, predict behavior under varying conditions, and ensure compliance long before a product leaves the lab.

As we explored in How to Build a Digital R&D Ecosystem: PLM, LIMS, and AI Together, the future of chemical R&D lies in breaking down silos between laboratory data, production parameters, and market feedback. Digital twins are the missing link that allows these data streams to become a living, continuously evolving model, enabling both innovation and compliance at scale.

2. What is a Digital Twin?

In scientific terms, a digital twin is a real-time, data-driven virtual representation of a physical entity, process, or system. It is not just a 3D model or a simulation; it’s a constantly updated reflection of the physical world, connected through sensors, data integrations, and feedback loops.

A digital twin for a chemical product typically consists of three interlinked layers:

Data Layer — Pulling information from PLM systems, LIMS outputs, manufacturing execution systems (MES), IoT sensors, and even external sources like weather or logistics data.

Simulation Layer — Incorporating both first-principles models (reaction kinetics, thermodynamics, computational fluid dynamics) and data-driven AI algorithms to predict behavior.

Feedback Loop — Ensuring continuous synchronization between the digital model and its real-world counterpart, so the twin evolves as conditions change.

According to Tao et al. (2021, Computers & Chemical Engineering), the power of digital twins in process industries lies in their ability to combine physics-based accuracy with machine learning adaptability, enabling predictions that improve with every new data point.

3. Why Digital Twins Matter in Chemical PLM

When embedded in a PLM platform, digital twins change the game for how chemical products are managed throughout their lifecycle.

From Idea to Formula Optimization — PLM already manages multiple formulation versions, but twins add real-world performance predictions before physical trials.

From Static Documentation to Predictive Systems — Instead of only recording what happened, PLM + twins can forecast what will happen under specific conditions.

From Isolated Compliance Checks to Continuous Verification — Digital twins can run constant simulations against evolving regulations, reducing approval delays.

From Reactive to Proactive Sustainability — As discussed in Circular Chemistry: How AI is Helping Close the Loop on Waste, twins can integrate lifecycle CO₂ calculations, waste projections, and recyclability scores into everyday decision-making.

4. Creating Digital Twins for Chemical Products

Building a digital twin of a chemical product is not a simple plug-and-play task; it requires careful orchestration of data integration, modeling, and continuous feedback mechanisms.

The journey starts with data aggregation. PLM systems hold product and formulation definitions; LIMS captures analytical results; MES provides operational parameters; IoT sensors track variables like temperature, viscosity, and pH during manufacturing. In some cases, even external datasets — such as climate data affecting raw material stability during transport — become critical inputs for the twin’s predictive accuracy.

Once the data backbone is in place, the next step is simulation modeling. At this stage, the twin evolves from a static repository to a dynamic predictive engine. Chemical reaction kinetics models can predict degradation pathways; computational fluid dynamics (CFD) can simulate how solvents mix or crystallization proceeds; AI algorithms can detect patterns in historical production data to improve model reliability. Research in Chemical Engineering Research and Design (Zhang et al., 2022) shows that blending physical models with AI-based learning consistently improves forecast precision in chemical processes.

Continuous synchronization is where the twin truly becomes “alive.” Any shift detected in the physical process — a deviation in reaction temperature, for example — immediately updates the twin’s dataset. The model recalculates likely outcomes and may recommend adjustments before product quality is compromised.

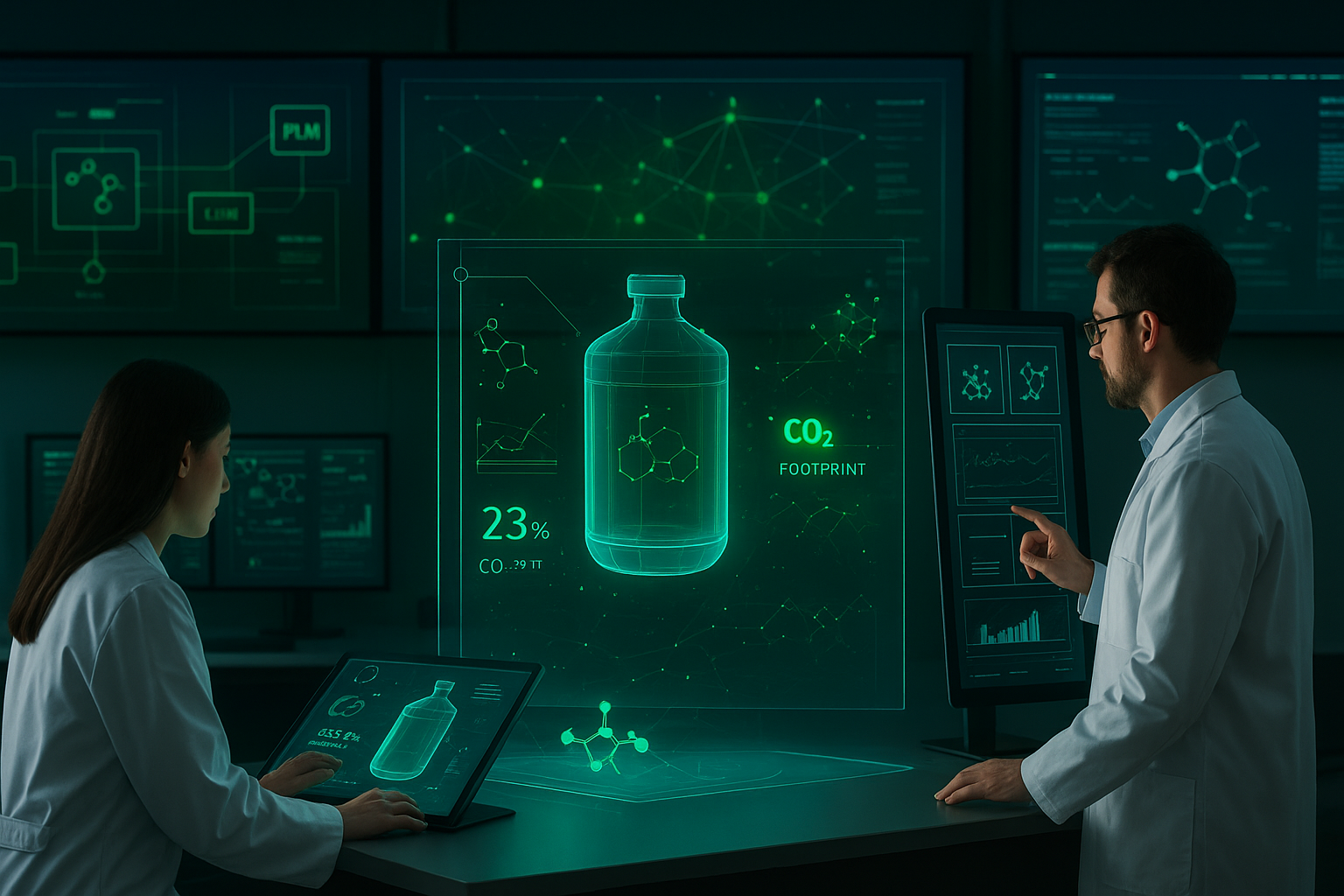

With this live feedback loop, companies can perform lifecycle analytics directly inside PLM: real-time CO₂ footprint calculations, multi-region compliance simulations, and predictive stability assessments. Over time, the twin becomes a strategic knowledge base, continually increasing in value as it learns from every batch, shipment, and market cycle.

Carbon footprint and waste generation can be calculated in real time, as discussed in Circular Chemistry: How AI is Helping Close the Loop on Waste.

5. AI’s Role in Chemical Digital Twins

Artificial intelligence transforms digital twins from static mirrors into adaptive problem-solvers.

For example, predictive shelf-life analysis uses machine learning models trained on years of stability studies to forecast how a product will behave under varying storage conditions — even before physical samples are tested. In toxicology risk assessment, AI-enabled twins can identify potential hazards earlier in the R&D process, aligning with methods we covered in our AI in Toxicology Analysis article.

Sustainability modeling is another domain where AI shines. By merging live production data with lifecycle assessment (LCA) algorithms, twins can estimate Scope 1, 2, and 3 emissions in near real time. This is where Chemcopilot’s CO₂ calculation capabilities fit perfectly, enabling side-by-side comparisons of different raw material options or process configurations for environmental impact.

As Patel et al. (2023, AIChE Journal) highlight, hybrid AI–physical models offer unmatched predictive power, especially in industries like chemicals where variability is high and process control is critical.

6. Benefits Across the Product Lifecycle

The value of a digital twin extends far beyond the lab.

In R&D, twins allow scientists to explore hundreds of virtual formulation variations without the cost and time of synthesizing each one. This agility supports faster innovation and easier adaptation to new market or regulatory demands.

During scale-up, twins act as a bridge between lab-scale recipes and full-scale manufacturing, flagging potential bottlenecks or yield losses before a single large batch is run.

In manufacturing, the twin becomes an active monitoring partner, detecting deviations within minutes and enabling course corrections before scrap rates spike.

Even post-market, twins provide insights into how products behave in real-world environments, feeding data back to improve the next iteration — a continuous loop of refinement that traditional PLM alone cannot achieve.

7. Sustainability and Regulatory Compliance

Sustainability in the chemical industry is no longer a branding exercise; it’s a competitive requirement. Digital twins enable virtual sustainability trials, where companies can test alternative feedstocks or packaging materials in the model before committing to costly physical trials.

This capability ties directly to our Bio-Based Chemicals vs. Petrochemicals article, where we explored the trade-offs between renewable and traditional feedstocks. With a twin, those trade-offs can be quantified for both technical performance and environmental footprint, reducing uncertainty in decision-making.

On the compliance side, twins can simulate how a product will fare under REACH, EPA, or FDA rules, allowing design adjustments long before formal submission. This proactive compliance verification reduces approval cycles and the risk of late-stage reformulations.

8. Implementation Challenges and Best Practices

While the potential is clear, implementing digital twins comes with challenges. Data silos remain a major barrier; integrating multiple systems and formats into a single coherent model requires both technical skill and organizational commitment.

Cybersecurity is another priority. Digital twins often house proprietary formulations and sensitive process data — making them prime targets for industrial espionage. Our PLM security best practices emphasize deploying twins in private cloud environments with zero model leakage to safeguard intellectual property.

Adoption is as much a cultural challenge as a technical one. Teams need time and evidence to trust the twin’s outputs. Successful implementations often start small, with a high-impact pilot in a single process area, and then scale up as confidence grows.

9. Future Outlook

The next generation of chemical digital twins will likely go beyond simulation into self-optimizing systems. AI-driven twins could autonomously adjust process parameters in real time, creating plants that continuously fine-tune themselves for efficiency, yield, and sustainability.

Integration with blockchain could enhance transparency, providing immutable lifecycle records from raw material origin to end-of-life recycling. Another emerging concept is Twin-as-a-Service, where suppliers offer pre-configured, validated digital twins for specific chemistries, drastically reducing setup times for manufacturers.

In short, the future points toward a world where physical and digital lifecycles are seamlessly intertwined, enabling chemical companies to innovate faster, comply smarter, and operate more sustainably.

10. Conclusion

Digital twins embedded in PLM represent one of the most transformative opportunities for the chemical industry today. They provide the agility to innovate faster, the foresight to anticipate compliance risks, and the tools to design for sustainability from day one.

With platforms like Chemcopilot — integrating AI, CO₂ tracking, and lifecycle data into a unified PLM environment — chemical companies can turn digital twins from an aspirational concept into a competitive advantage. The result is not just better products, but better chemistry: more efficient, more compliant, and more sustainable.

Editor’s Note:

If you’re exploring the fundamentals of digital twins in the chemical sector, you may also want to read two related Chemcopilot articles:

• The Rise of Digital Twins in Chemical Manufacturing: How AI is Creating Virtual Factories — focusing on plant-level applications like predictive maintenance, emissions monitoring, and self-optimizing operations.

• The Future of PLM: AI, Digital Twins, and Smart Data for Chemical Innovation — covering how PLM systems are evolving from static repositories to proactive engines for formulation, sustainability, and compliance.