The 2026 Pharma Blueprint: How AI, Molecular Docking, and DOE are Engineering the Future of APIs

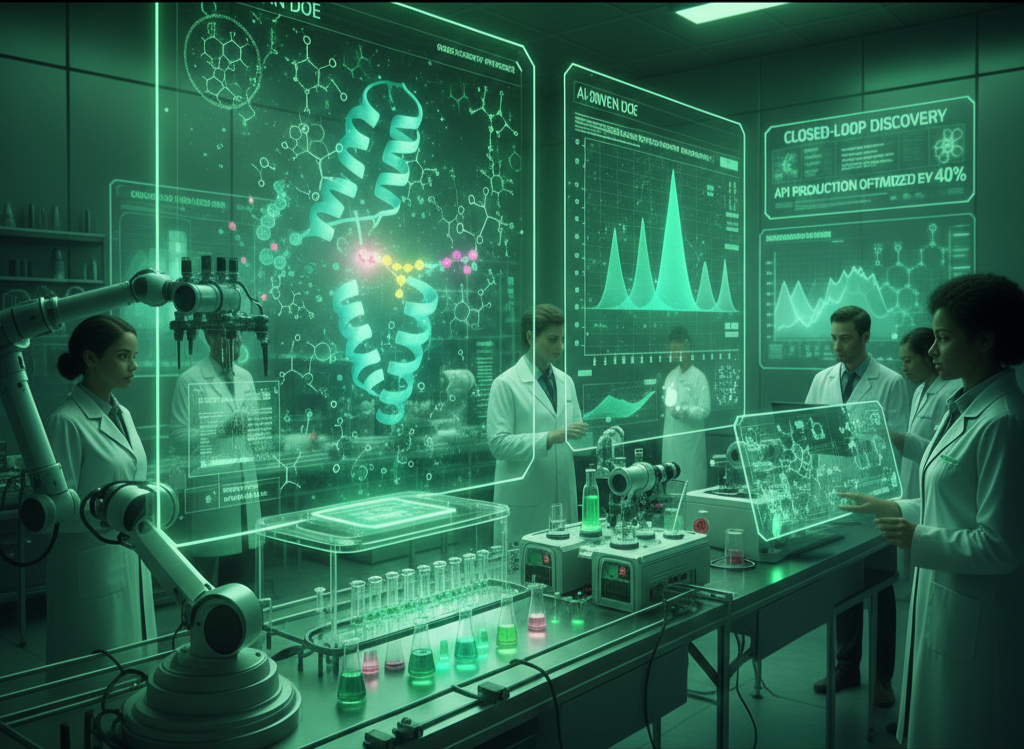

In the pharmaceutical world of 2026, the days of "trial and error" are officially over. We have moved beyond simple automation into the era of the "Self-Driving Lab," where the journey from a digital concept to a physical Active Pharmaceutical Ingredient (API) is a seamless, AI-orchestrated loop.

By integrating Molecular Docking with Design of Experiments (DOE), pharma companies are no longer just discovering drugs—they are engineering them with mathematical precision and unprecedented speed.

1. The Discovery Spark: AI-Powered Molecular Docking

Every life-saving drug starts with a fundamental question: Does this molecule actually work? Molecular Docking is the computational simulation used to answer that. It predicts how a potential drug molecule (the ligand) binds to a target protein in the body.

In 2026, AI models like AlphaFold 3 and advanced diffusion-based docking have turned this from a slow physics-heavy problem into a lightning-fast data task.

Massive Virtual Screening: AI can now "dock" billions of compounds against a disease target in mere hours, identifying the "perfect fit" with 50% more accuracy than a decade ago.

Dynamic Binding Affinity: Modern docking doesn't just find a static match; it simulates the molecular flexibility of both the protein and the ligand, ensuring the API remains effective in the complex, moving environment of the human body.

2. The Strategy: AI-Driven Design of Experiments (DOE)

Once docking identifies a "winning" molecule, the challenge shifts from biology to chemistry: How do we make it efficiently? This is where Design of Experiments (DOE) enters the frame.

Traditional DOE was a manual statistical method limited by human cognitive capacity. Today, AI-enhanced DOE uses machine learning to map out the entire chemical reaction space before the first beaker is touched.

Multi-Objective Optimization: AI simultaneously balances competing goals—maximizing yield and purity while minimizing "green" metrics like solvent waste and energy consumption.

Predictive Mapping & Failure Analysis: Instead of testing one variable at a time (temperature, pressure, pH), AI runs thousands of virtual simulations. This identifies "red zones" where the API might degrade or form toxic byproducts, preventing costly batch failures in the plant.

Adaptive Learning: As physical experiments are conducted, the data is fed back into the AI model, which "re-designs" the next set of experiments in real-time to zero in on the optimal process.

3. The Result: Precision API Production & The "Green" Revolution

The final stage of the loop is the physical creation of the API. In 2026, the data from the docking and DOE phases flows directly into "smart factories" equipped with Process Analytical Technology (PAT).

The integration of these three pillars creates a Closed-Loop Discovery system:

Docking finds the right molecule.

DOE finds the most stable and scalable way to build it.

API Production executes the plan, using "Digital Twins" to monitor every drop in real-time.

The Regulatory Edge: One of the biggest hidden benefits in 2026 is Compliance by Design. Because AI-driven DOE provides a complete mathematical "map" of the process, regulatory bodies like the FDA can approve new manufacturing routes faster, knowing that every variable has been accounted for and validated.

Why This Matters for 2026 and Beyond

The synergy between these technologies is solving pharma’s biggest historical bottlenecks. We are seeing a shift toward:

Sustainable Chemistry: AI-DOE has reduced the industry's carbon footprint by identifying catalysts that work at lower temperatures and reducing solvent waste by over 30%.

Global Agility: When a raw material supply chain breaks, AI can quickly redesign the DOE to use an alternative starting material, ensuring that life-saving APIs remain in production.

Hyper-Speed Development: Molecules that once took five years to reach the lab are now arriving in eighteen months, drastically reducing the "cost per cure."

Conclusion

The integration of Molecular Docking, AI-driven DOE, and API manufacturing is more than a technical upgrade—it’s a revolution. We are moving away from the "art" of chemistry and toward a disciplined, high-velocity engineering model. This integrated approach doesn't just make drugs faster; it makes them safer, greener, and more accessible to the patients who need them most.