AI in India’s Chemical MSMEs: From Survival Tool to Competitive Advantage — And Where ChemCopilot Fits in the Global Industrial Intelligence Shift

The chemical manufacturing landscape is often narrated through the lens of multinational conglomerates, billion-dollar refineries, and high-visibility research laboratories. Yet, beneath this global narrative lies a vast, largely uncharted ecosystem — mid-scale and small chemical manufacturers, particularly in emerging economies such as India. These enterprises do not merely constitute an economic statistic; they represent an intricate network of production intelligence, regional innovation, and adaptive engineering.

Artificial Intelligence, in this context, has not emerged as a luxury or a futuristic indulgence. For many Chemical MSMEs (Micro, Small, and Medium Enterprises), AI is evolving from a survival mechanism into a strategic differentiator. The transformation is neither cosmetic nor superficial; it is structural, altering how decisions are made, how resources are allocated, and how risk is quantified.

Understanding AI in Chemical Manufacturing — Beyond Automation

Artificial Intelligence in chemical industries is frequently misinterpreted as a synonym for robotics or process automation. In reality, the true value of AI lies in cognitive augmentation rather than mechanical substitution.

AI systems in chemical environments analyze molecular datasets, production metrics, safety logs, regulatory frameworks, and supply chain variables simultaneously — a computational scale unattainable through manual oversight. This enables predictive insights instead of reactive corrections.

For MSMEs, this distinction is pivotal. Large corporations often possess the financial elasticity to absorb inefficiencies; smaller enterprises do not. AI therefore becomes an economic equalizer, allowing mid-scale manufacturers to operate with precision previously exclusive to industrial giants.

The Indian MSME Chemical Ecosystem — A Silent Innovation Engine

India hosts one of the most diverse chemical MSME ecosystems globally. These firms operate across polymers, dyes, agrochemicals, specialty intermediates, and fine chemicals. Their challenges, however, are multidimensional:

Volatile raw material pricing

Regulatory compliance complexity

Safety and hazard management

Energy efficiency constraints

Limited R&D capital

AI integration within this sector is not about replacing human chemists; it is about empowering them with computational foresight. When mid-size manufacturers leverage intelligent analytics, they unlock improvements in yield optimization, batch consistency, predictive maintenance, and regulatory forecasting.

This phenomenon is not exclusive to India. Similar patterns are observable in Southeast Asia, Eastern Europe, and Latin America — making the discussion globally relevant while remaining regionally grounded.

What Is ChemCopilot? — Clarifying the Concept Without Ambiguity

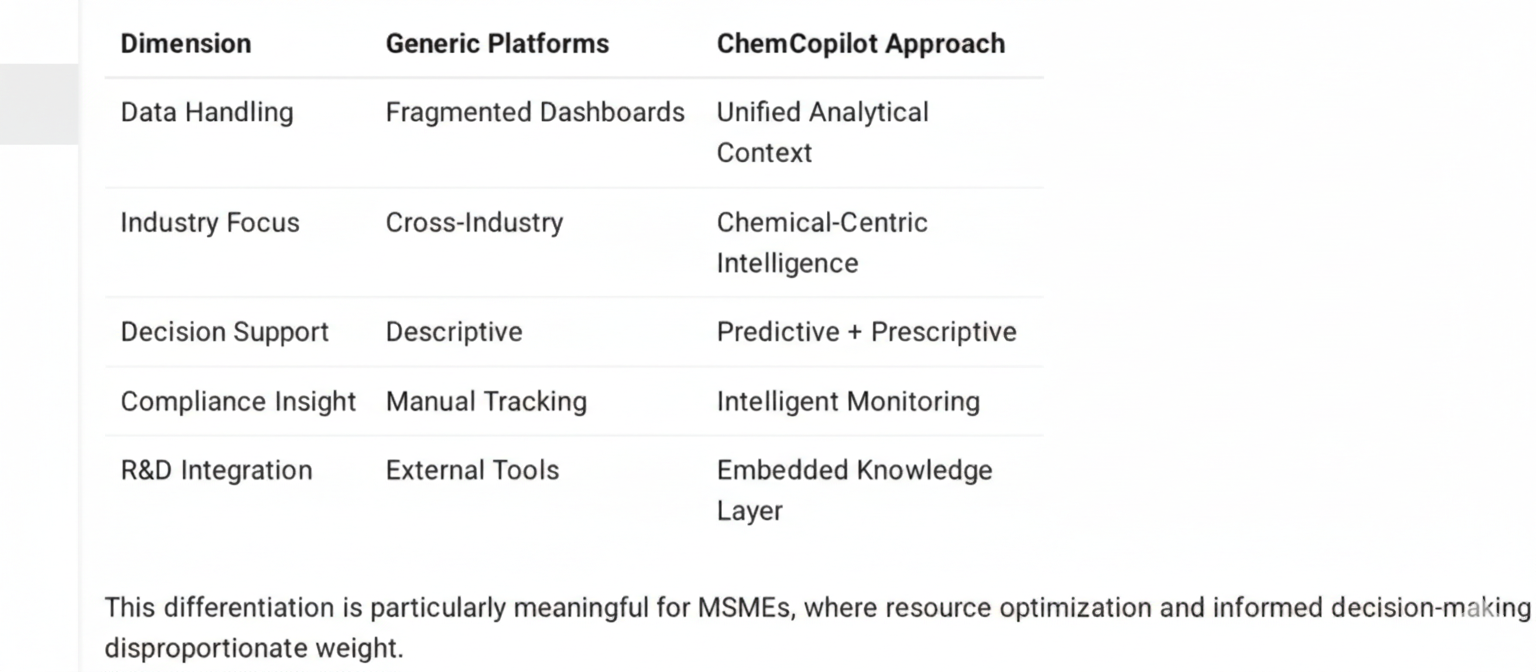

ChemCopilot is not merely an automation platform, nor is it a generic AI tool retrofitted for chemical industries. Its conceptual foundation lies in domain-specific intelligence — an ecosystem designed to interpret chemical manufacturing data, research insights, compliance structures, and operational variables in a unified analytical framework.

Where conventional platforms provide isolated solutions — such as ERP dashboards, scheduling software, or data visualization modules — ChemCopilot functions as an industrial cognition layer. It contextualizes data rather than merely displaying it.

From Survival to Strategic Advantage — The Inflection Point

The transition from operational survival to competitive advantage occurs when AI shifts from problem-solving to opportunity-identification.

At the survival stage, AI assists in reducing downtime, minimizing wastage, and maintaining safety compliance. At the strategic stage, it begins to influence product innovation, market positioning, and research direction.

For chemical MSMEs, this progression represents an intellectual leap rather than a technological upgrade. It signifies moving from reactive production to anticipatory manufacturing — a paradigm where data becomes an asset instead of an afterthought.

Global Relevance — Why This Is Not an India-Only Narrative

While India provides a compelling case study due to its industrial diversity and MSME density, the underlying dynamics resonate worldwide. Nations striving for industrial self-reliance, sustainable manufacturing, and technological modernization encounter identical inflection points.

ChemCopilot’s conceptual utility lies in its scalability across geographies. Whether applied to a polymer manufacturer in Gujarat, a specialty chemical producer in Germany, or a pharmaceutical intermediate plant in Brazil, the core principle remains constant: intelligent contextualization of chemical data ecosystems.

The Research Dimension — Bridging Academia and Industry

A frequently overlooked aspect of AI in chemical manufacturing is its potential to harmonize academic research with industrial application. Students, scientists, and researchers often generate high-value insights that remain confined to journals or thesis repositories.

An intelligent platform can function as a translational bridge — converting theoretical research into operational guidance. This convergence fosters an environment where innovation is not episodic but continuous, enabling MSMEs to participate in cutting-edge advancements without disproportionate capital expenditure.

ChemCopilot as an Enabler, Not a Replacement

The most sophisticated AI systems do not seek to replace chemists, engineers, or researchers. Their value lies in amplifying human expertise. ChemCopilot’s conceptual positioning is aligned with augmentation rather than automation.

It serves as a collaborative intelligence interface — assisting professionals in pattern recognition, regulatory navigation, and strategic foresight while preserving the indispensability of human judgment. This synergy transforms AI from a technological tool into an intellectual partner.

Conclusion — The Emergence of Industrial Intelligence as a Competitive Language

The discourse surrounding AI in chemical MSMEs is not a futuristic hypothesis; it is an unfolding industrial reality. As enterprises transition from operational resilience to strategic differentiation, platforms that contextualize knowledge, integrate research, and enable predictive decision-making become indispensable.

ChemCopilot represents a paradigm where industrial intelligence evolves into a shared language between scientists, manufacturers, and strategists. In this landscape, AI is neither a novelty nor a threat — it is a catalyst that transforms fragmented data into coherent foresight, enabling chemical enterprises of every scale to compete on a global intellectual stage rather than merely a financial one.