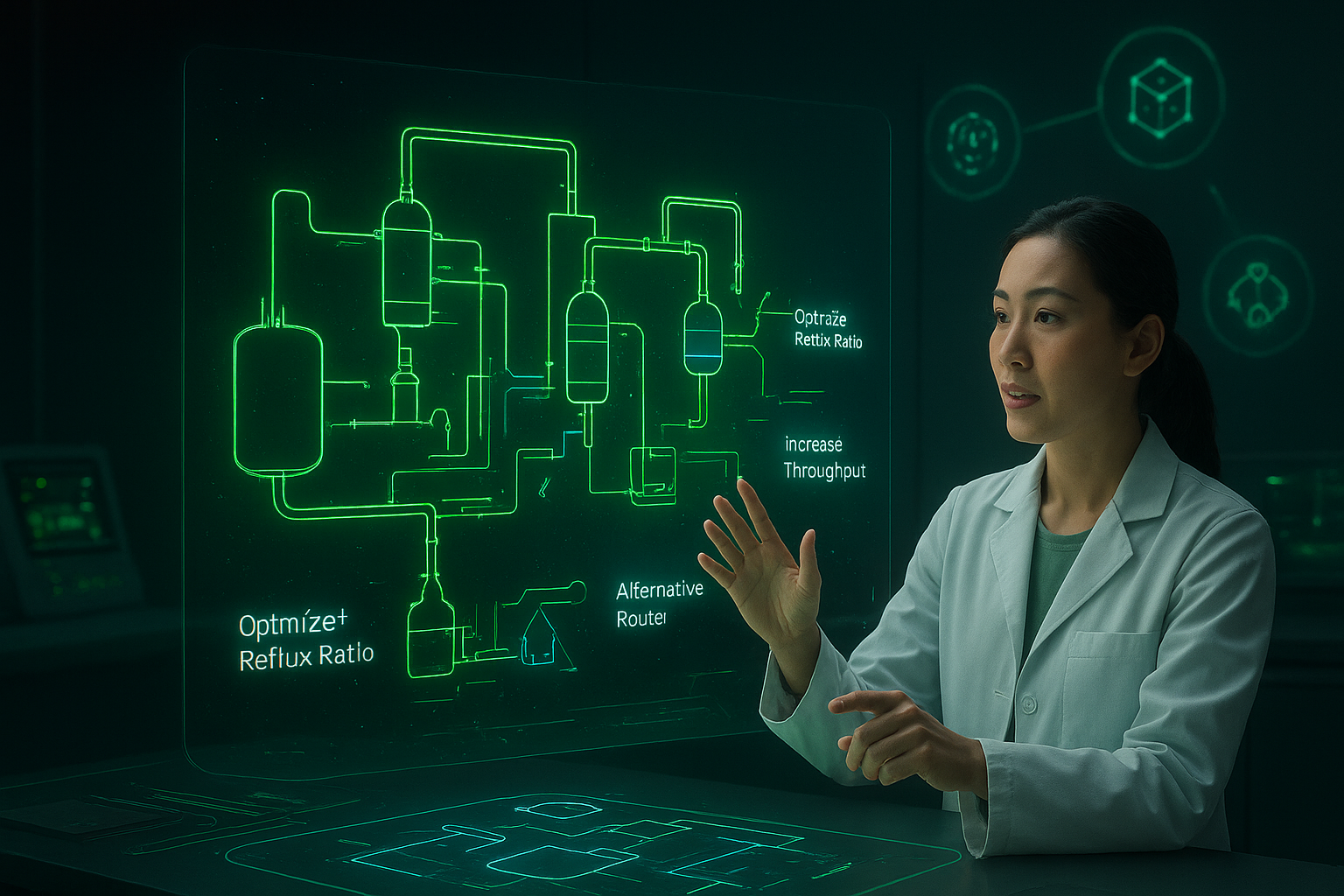

Introducing Chemcopilot’s Interactive Demo Environment: Talk, Draw, and Optimize Any Chemical Process With AI

The chemistry industry is moving toward an era where designing, simulating, and optimizing processes happens in minutes rather than months. Chemcopilot’s new interactive demo environment represents this shift. It is a space where users can talk directly with an AI agent, draw their own process flows, customize any step, and immediately receive intelligent optimization suggestions.

While this is only one of the possible user paths in Chemcopilot, it demonstrates how AI can become the engine of future R&D and operations.

A New Way to Explore Chemical Processes

Inside this environment, the workflow becomes intuitive and conversational. You describe the process you want to design, whether it is a distillation train, a polymerization route, an extraction line, or a wastewater treatment sequence. The AI interprets your goals, constraints, operational context, and the scientific logic behind each step.

You can then draw the process visually, arranging tanks, reactors, heat exchangers, feed lines, utilities, and waste streams. The system recognizes each element and converts the diagram into meaningful engineering logic. Parameters such as temperature, flow rate, residence time, solvent ratio, energy demand, or reagent purity can be adjusted visually or through natural language.

If you say, “Increase the reflux ratio but keep the CO₂ footprint within 5% of baseline,” the AI understands both the engineering intentions and the sustainability constraints.

From there, the system analyzes the entire configuration and proposes improvements—alternative routes, energy savings, yield enhancements, solvent substitutions, bottleneck removal, or safety corrections. It can also estimate environmental indicators, resource consumption, and potential compliance concerns. The result is a smooth, intelligent, human-AI interaction for building and refining chemical processes.

This demo illustrates how Chemcopilot’s AI can support decision-making at every level of complexity.

Beyond the Demo: A Network of AI Agents for the Entire Chemical Lifecycle

Demo: Distilation Process

What makes this environment powerful is not the diagramming tool itself, but the broader ecosystem that surrounds it. Chemcopilot operates through multiple specialized AI agents, each designed to support a critical layer of chemical innovation.

The Process Design and Optimization Agent is only one component. Other agents include a PLM agent that structures all formulations, specifications, tests, materials, and versioning; a no-code formulation agent that learns from internal lab data; regulatory intelligence that instantly integrates global restrictions into your workflow; lifecycle and carbon analysis that quantifies CO₂ and environmental metrics; and a digital twin agent that simulates full plant behavior under changing conditions.

Each agent reinforces the others. Together, they create an AI-native R&D and manufacturing ecosystem that understands context, harmonizes information, and elevates chemical development into a fully connected digital environment.

Why This Matters for the Future of Chemical Innovation

Chemical R&D and operations have historically relied on isolated tools and fragmented data. Formulators work with spreadsheets, engineers use process simulators, regulatory teams use separate databases, and sustainability assessments are performed late in the process.

Chemcopilot removes these barriers.

By enabling users to describe processes in natural language, visualize them instantly, customize parameters, validate sustainability, and connect everything to PLM and digital twin data structures, the platform becomes a single intelligent environment for the entire organization.

AI acts as the central layer that understands intentions, performs calculations, analyzes risk, automates documentation, and connects decisions across R&D, compliance, plant design, and scale-up. This is how a modern chemistry organization gains speed, clarity, and resilience.

What Users Will Experience Inside the Demo

The new environment offers a guided experience where AI assists at every step. Users can build flows, refine parameters, and explore alternatives with seamless transitions between conversation, drawing, and optimization. The interaction feels more like collaborating with an expert than using a traditional software interface.

The demo also showcases how naturally the process tool integrates with Chemcopilot’s other AI agents. Every action you take—changing a solvent, adjusting a temperature, modifying a raw material—can be extended to formulation logic, regulatory checks, CO₂ evaluation, and system-wide simulation.

This gives users a first look at how AI-native laboratories and plants will function in the coming years.

A First Step Toward the AI-Native Chemical Ecosystem

This new interactive demo is only the starting point. Chemcopilot is creating a future where multiple AI agents work together, each one specialized in a different dimension of chemistry. Processes, documents, experiments, sustainability data, and compliance logic all become connected and self-updating. Engineers, researchers, and product teams gain a digital environment that thinks, reasons, and adapts with them.

The demo provides a glimpse into this world—a place where you can design a process by talking to the system, visualize ideas instantly, and receive intelligent, scientifically grounded recommendations. It shows how AI can become the foundation for faster research cycles, safer decisions, lower environmental impact, and more innovative products.

Chemcopilot’s vision is clear:

an AI-native architecture that transforms knowledge into action across the entire chemical value chain.

Acess here: https://demo.chemcopilot.com/