The Architect of Efficiency: Why AI-Driven DOE is the New Gold Standard for Pharmaceutical Quality

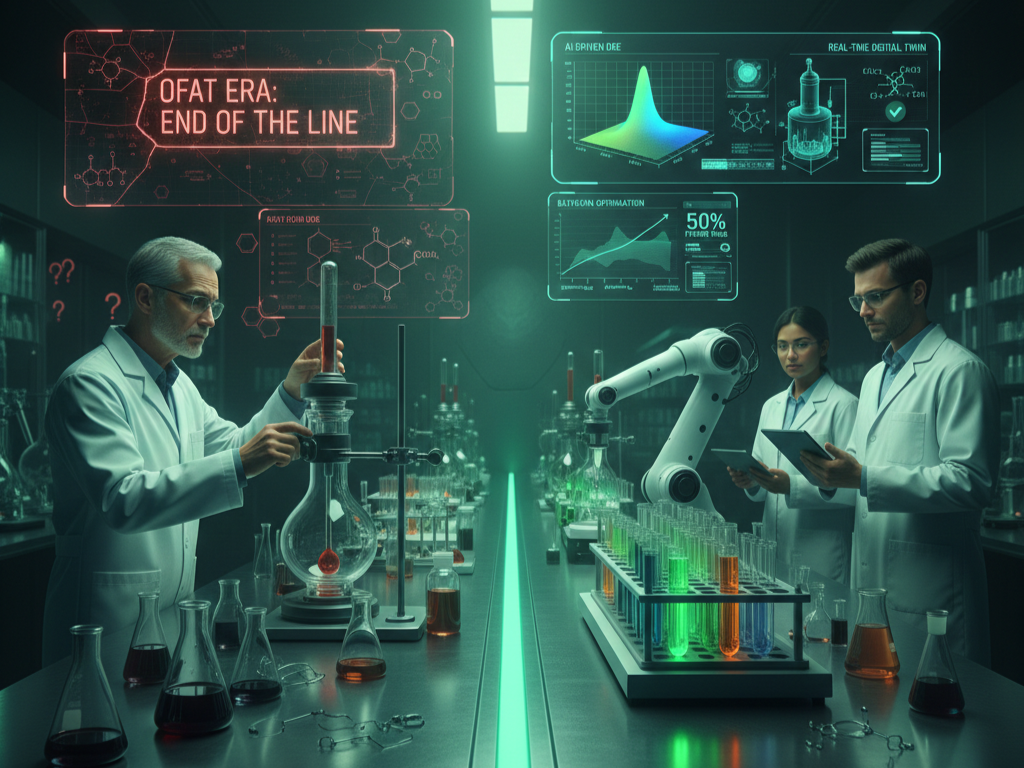

The End of the "One-Factor-at-a-Time" Era

For decades, pharmaceutical process development relied on a method known as OFAT (One-Factor-at-a-Time). A chemist would change the temperature while keeping every other variable constant, observe the result, and then move on to the next variable, like pH or pressure.

In 2026, we recognize OFAT for what it truly is: a bottleneck. It is mathematically impossible for a human to track the complex, non-linear interactions between dozens of variables simultaneously. Enter Design of Experiments (DOE)—a systematic approach that varies multiple factors at once to reveal the hidden "synergies" and "antagonisms" within a chemical reaction. When supercharged by Artificial Intelligence, DOE becomes the brain of the "Self-Driving Lab."

1. The Core Philosophy of DOE: Understanding Interaction Effects

The primary reason to use DOE over traditional methods is the Interaction Effect. In API synthesis, Factor A (Temperature) might not have a significant effect on its own, and Factor B (Agitation Speed) might seem irrelevant. However, when both are high, they might trigger a catastrophic degradation of the molecule.

AI-driven DOE identifies these "multi-dimensional" relationships. By using a structured matrix of experiments, researchers can map out the entire Response Surface, identifying not just a single "good result," but a robust Design Space where quality is guaranteed.

2. The DOE Lifecycle: From Screening to Optimization

In a 2,000-word exploration, we must distinguish between the two primary stages of the DOE journey:

Phase I: Screening (Identifying the "Vital Few")

At the start of an API project, there may be 15 or 20 variables that could affect yield. Testing them all would be prohibitively expensive. AI-DOE uses Fractional Factorial Designs or Plackett-Burman Designs to quickly filter out the "trivial many" and identify the "vital few" factors that actually drive quality.

Phase II: Optimization (Finding the "Sweet Spot")

Once the critical factors are identified, the AI shifts to higher-order designs like Central Composite Design (CCD) or Box-Behnken. These designs allow for curvature in the data—meaning the AI can find the peak of a "mountain" of efficiency rather than just following a straight line.

3. Quality by Design (QbD) and Regulatory Compliance

In 2026, the FDA and EMA are no longer just looking for "batch results"; they are looking for process understanding. This is codified in the Quality by Design (QbD) framework.

DOE provides the mathematical proof required for ICH Q8 (Pharmaceutical Development). By presenting a validated Design Space, a pharmaceutical company can prove that as long as they stay within certain parameters, the API will always meet its specifications. This reduces the need for "end-product testing" because quality is built into the process itself.

4. The AI Revolution: Adaptive and Bayesian DOE

What makes DOE in 2026 different from DOE in 2010? Active Learning.

Traditional DOE required all experiments to be planned upfront. AI-DOE (Active Learning) is iterative. The AI analyzes the data from the first three runs and uses Bayesian Optimization to suggest the next three runs. This "Closed-Loop" approach often reaches the optimal solution in 50% fewer experiments than traditional static DOE.

5. Overcoming the "Black Box" Challenge

One of the major hurdles to AI-DOE adoption is the fear of the "Black Box"—the idea that we don't know why the AI chose a specific setting. To counter this, the industry has turned to Explainable AI (XAI). Modern DOE software now provides "Shapley Values" or "Feature Importance" charts, showing chemists exactly which chemical mechanism is driving the AI's recommendations.

6. Real-World Impact: Case Studies in 2026

Case Study A: Reducing Solvent Waste. A mid-sized biotech used AI-DOE to optimize a hydrogenation reaction. By identifying a specific interaction between catalyst loading and hydrogen pressure, they reduced solvent consumption by 34%.

Case Study B: Scaling Up a Biologic. In the production of a complex monoclonal antibody, DOE identified that a micro-fluctuation in dissolved oxygen was the culprit for protein misfolding, a factor that had been missed for six months using OFAT.

7. The Future: Digital Twins and Real-Time DOE

The ultimate goal of DOE is to move from the lab to the "Digital Twin." Once a process is fully mapped via DOE, a virtual model of the reactor is created. If a sensor in the physical factory detects a slight change in the raw material quality, the DOE-informed AI calculates a "real-time correction" to the temperature or flow rate, ensuring the batch is never lost.

Conclusion: The New Strategic Imperative

Design of Experiments is no longer a "nice-to-have" statistical tool; it is the fundamental language of 21st-century pharmaceutical engineering. By embracing AI-driven DOE, companies are not just saving time and money—they are ensuring that life-saving medications are more stable, more affordable, and more sustainable.