One Formulation, Five Regulations : Why Indian Chemical R&D Needs Context-Aware Intelligence

In Indian chemical laboratories, failure rarely announces itself loudly.

More often, it arrives quietly—after the chemistry is solved, after the formulation performs as intended, after the science has already done its work. The problem is not that the product does not function. The problem is that it cannot move.

It stalls somewhere between approval and adoption, between the lab bench and the market, caught not by a lack of innovation but by an excess of interpretation.

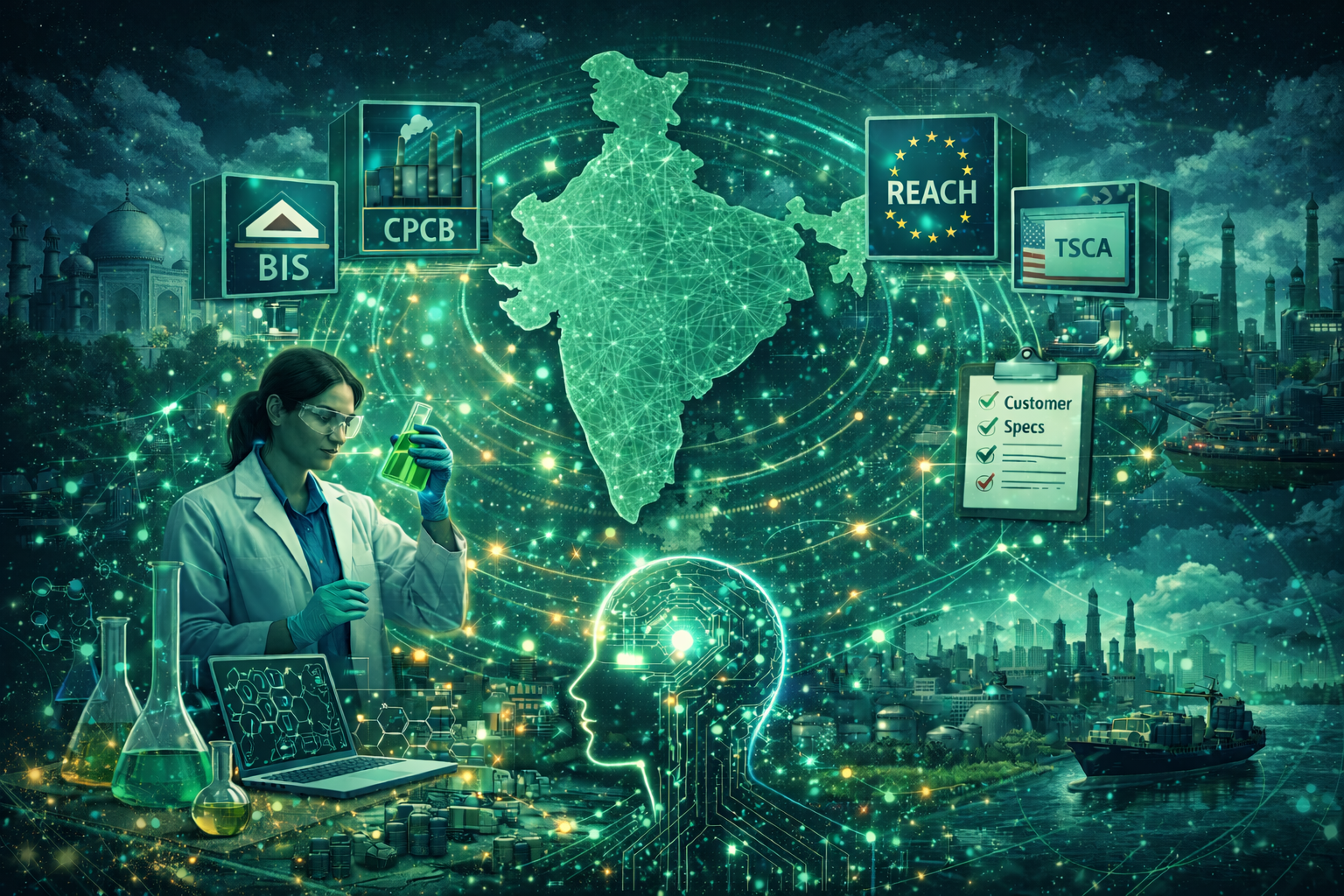

A single formulation, developed with care and competence, must satisfy not one authority but many. It must be legible to domestic quality standards, environmentally defensible under operational scrutiny, interpretable across international regulatory regimes, and acceptable to customers whose specifications often exceed statutory requirements. Each system evaluates the same formulation differently. Each speaks its own language. None waits for the others to catch up.

This is the quiet tension shaping modern Indian chemical R&D.

A formulation is never just a formulation

Inside the lab, a formulation is a scientific object.

It is evaluated through stability, performance, reproducibility, yield. It is something that can be optimized, tuned, and improved.

But the moment it begins its journey outward, it acquires additional identities.

Under quality frameworks, it becomes a standard-bound object—defined by test methods, thresholds, and conformance claims.

Under environmental oversight, it becomes an operational object—its meaning shaped by waste streams, storage practices, emissions, and disposal routes.

Under international regulations, it is reinterpreted again, this time as a constellation of substances with hazard classifications, restrictions, and reporting obligations.

And under customer specifications, it becomes a contractual object, judged not only by law but by trust, risk perception, and brand consequence.

None of these identities is artificial. All are real. The difficulty lies in the fact that they are rarely visible at the same time.

Indian R&D teams are often asked to design chemistry first and reconcile these identities later. The reconciliation, when it comes late, is expensive—not only in cost and time, but in lost momentum. A formulation that once felt promising becomes fragile, vulnerable to reinterpretation under a different lens.

Regulation in India is not a static backdrop—it is a moving field

This fragility is intensified by the nature of regulation itself.

In India, regulatory expectations do not remain fixed long enough to be treated as background conditions. Standards evolve. Quality frameworks shift from advisory to mandatory. Environmental scrutiny deepens as enforcement priorities change. Export obligations expand as companies seek global markets.

What was compliant yesterday may remain chemically identical yet become contextually insufficient today.

This creates a form of instability that is difficult to capture in documents. Compliance is no longer something achieved at a single point in time; it is something that must be maintained across time. The formulation does not change—but the way it is judged does.

Human expertise is not designed for this kind of continuous contextual vigilance. Scientists are trained to reason deeply, not endlessly. Asking them to repeatedly translate the same formulation across shifting regulatory frames is not a question of skill—it is a question of cognitive load.

Over time, that load reshapes behavior.

The unseen tax on innovation

Most delays in Indian chemical R&D do not come from dramatic regulatory failures. They come from accumulation.

A solvent substitution that improves cost but alters waste classification.

A trace ingredient that passes domestic review but raises flags under export logic.

A scale-up decision that transforms benign lab residues into regulated industrial waste.

A customer requirement that quietly overrides what regulation allows.

Each issue, taken alone, is manageable. Together, they create a persistent drag on progress.

This drag is rarely acknowledged as a systemic problem. Instead, it manifests as caution. Teams hesitate earlier. Experiments are narrowed sooner. Ideas are abandoned not because they are unworkable, but because the effort required to prove their viability across contexts feels disproportionate.

Innovation does not stop. It becomes careful. And care, while necessary, can slowly erode ambition when it is driven by uncertainty rather than intention.

The missing layer is not more rules, but more continuity

What Indian chemical R&D lacks is not knowledge. It is continuity of context.

Formulation data exists. Regulatory expertise exists. Operational understanding exists. Customer requirements exist. What is missing is a way for these perspectives to remain connected as the formulation evolves.

Context-aware intelligence addresses this gap not by automating judgment, but by preserving relationships.

When a formulation changes, its implications across quality standards, environmental handling, international regulations, and customer constraints remain visible. Nothing is hidden downstream. Nothing must be rediscovered later. The formulation carries its contexts with it as it moves.

This changes the texture of work.

Compliance no longer interrupts creativity. It accompanies it.

Operational consequences no longer appear as late surprises. They are anticipated.

Export readiness becomes a property of the formulation, not a separate project.

Scientists regain something that is often lost in complex systems: confidence that exploration will not unravel later.

Why this matters uniquely in India

Indian chemical organizations operate under a distinctive convergence of pressures: rapid cost sensitivity, diverse portfolios, uneven infrastructure maturity, and simultaneous domestic and global aspirations.

In such an environment, speed without context leads to rework. Caution without clarity leads to stagnation.

The ability to move quickly with awareness becomes a strategic advantage.

When regulatory, operational, and customer contexts are integrated into the same intellectual space as formulation design, organizations begin to behave differently. Knowledge stops leaking between departments. Decisions made early remain intelligible later. The lab, the plant, and compliance no longer function as sequential checkpoints, but as parts of a single thinking system.

This is not a technological transformation so much as an organizational one.

From late-stage correction to early-stage confidence

The deepest impact of context-aware systems is not efficiency—it is psychological safety.

When teams trust that implications are visible early, they take better risks. They iterate with intention. They scale with steadiness rather than anxiety.

Compliance stops being a moment of reckoning and becomes a source of orientation.

In a country where chemical innovation must be both fast and credible, this shift is subtle but profound. It does not announce itself in dashboards or slogans. It reveals itself in fewer abandoned formulations, calmer scale-ups, and ideas that survive the journey from conception to commercialization without losing their coherence.

A quiet form of readiness

The future of Indian chemical R&D will not be determined solely by laboratory brilliance or regulatory vigilance. It will be shaped by the ability to hold complexity without being slowed by it.

Context-aware intelligence does not promise freedom from regulation. It offers something more realistic and more valuable: the ability to think clearly inside constraint.

That clarity—quiet, sustained, and deeply practical—may well define the next phase of Indian chemical innovation.